Rettificatrici a centro mobile

Serie CG.R.

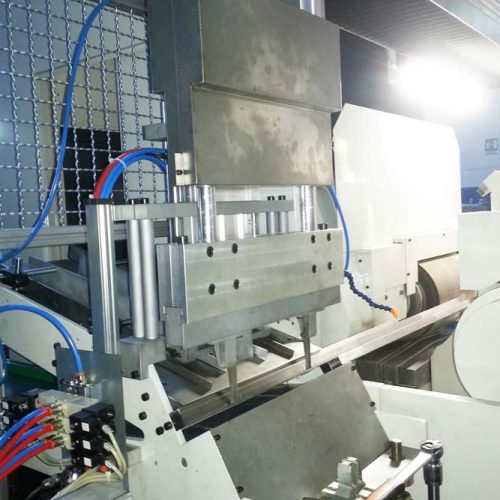

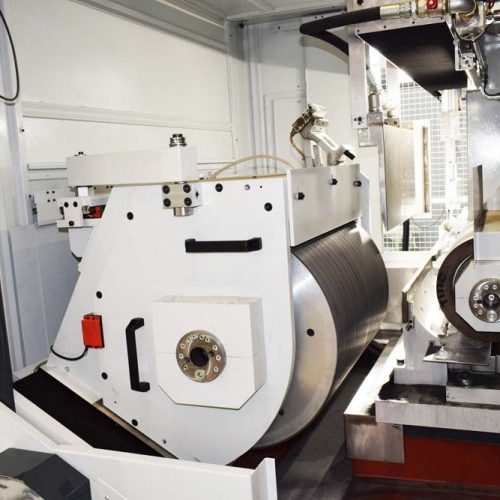

Macchina estremamente versatile e robusta che copre qualsiasi tipo di lavorazione. Basamento monoblocco in ghisa. Soli 3 assi CN per la realizzazione della macchina base che gestiscono sia i cicli di lavoro che quelli relativi alla profilatura della mola operatrice e della mola conduttrice. Slitta trasversale portante la mola operatrice a controllo numerico, inclinata di 30° per ridurre al minimo la distanza tra guide e centro mola, rendendo la struttura più compatta e rigida. Il movimento assiale della mola operatrice, permette la rettifica di particolari con “sotto-testa” e la lavorazione delle barre in metallo duro con una nuova tecnologia oscillante per ottenere valori di “run-out” minimi.

- da CG.R 500/250 a CG.R 600/350 con mandrino mola operatrice idrodinamico, mola conduttrice con mandrino a bronzine a bagno d’olio.

- da CG.R 600/400 a CG.R 600/500 con entrambi mandrini speciali idrostatici. L’albero fisso e il solo corpo mola rotante consentono di garantire la massima rigidità.

Tecnologia Green a basso impatto ambientale

Alta efficienza energetica

Macchina digitale Industry 4.0 Ready

| CG.R 600/200 | CG.R 600/300 | CG.R 600/500 | CG.R600/400 Speciale * (HM) | CG.R600/680 Speciale * (HM) | CG.R 500/250 | |

|---|---|---|---|---|---|---|

| POSSIBILITÀ PRODUTTIVA | ||||||

| Diametri pezzi | Ø3÷Ø200mm | Ø3÷Ø300mm | Ø4÷Ø300mm | Ø4÷Ø200mm | Ø4÷Ø200mm | Ø4÷Ø100mm |

| Lunghezza rettificabile con lavorazione a tuffo | 200mm | 350mm | 500mm | 400mm | 700mm | 250mm |

| CARATTERISTICHE MOLE - ASSI CNC | ||||||

| Diametro mola operatrice | Ø610mm | Ø610mm | Ø610mm | Ø610mm | Ø610mm | Ø508mm |

| Larghezza mola operatrice | 200mm | 350mm | 500mm | 400mm | 680mm | 250mm |

| Foro mola operatrice | Ø304,8mm | Ø304,8mm | Ø304,8mm | Ø304,8mm | Ø304,8mm | Ø304,8mm |

| Diametro mola conduttrice | Ø350mm | Ø350mm | Ø350mm | Ø350mm | Ø350mm | Ø300mm |

| Larghezza mola conduttrice | 200mm | 350mm | 400 ÷ 700mm | 400 ÷ 700mm | 700mm | 400mm |

| Foro mola conduttrice | Ø203,2mm | Ø203,2mm | Ø203,2mm | Ø203,2mm | Ø203,2mm | Ø152,4mm |

| Velocità periferica mola operatrice | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s |

| Velocità mola conduttrice | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m |

| Compensazione minima (positiva/negativa) | 0,0005mm | 0,0005mm | 0,0005mm | 0,0005mm | 0,0005mm | 0,0005mm |

| n° assi CNC (esclusi accessori) | 3 | 3 | 3 | 3 | 3 | 3 |

| POTENZE | ||||||

| Potenza motore mola operatrice | 22kW | 36kW | 49kW | 49kW | 55kW | 22kW |

| Potenza motore mola conduttrice | 3kW | 3kW | 5,5kW | 5,5kW | 5,5kW | 3kW |

| Potenza installata | 42kW | 56kW | 70kW | 70kW | 75kW | 42kW |

| CARATTERISTICHE GENERALI | ||||||

| Peso totale macchina + servizi (senza accessori) | 9500kg | 10500kg | 13500kg | 13500kg | 14500kg | 11500kg |

| Ingombro a terra macchina + servizi (senza accessori) | 4 x 3m | 4 x 3,3m | 4 x 3,3m | 4,3 x 4m | 4,3 x 4m | 3,8 x 3m |

Assistenza

Hai bisogno di risolvere un problema per la tua rettificatrice senza centri?